ABOUT

JING-JANG

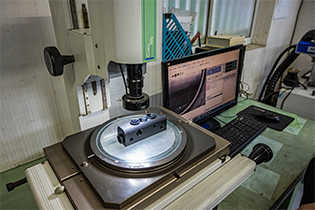

Jingjang Company has advanced software, coupled with sophisticated instruments and mechanical equipment, including:

Xianjie EDM and Xianjie CNC EDM:

We have introduced 6 electric discharge machines and 3 CNC electric discharge machines, and use their discharge to generate high temperatures for processing operations.

Yongjin CNC comprehensive processing machine:

We introduced 3 processing machines programmed using Power Mill and UG. After program conversion, the main functions are milling electrodes, male and female mold cores and mold parts.

Quick milling machine:

The rotating multi-blade tool is mainly used for milling the contours of each groove (non-curved surface) of the mold.

Deckel Maho five-axis integrated machining machine:

In order to enhance the processing accuracy of mold products, we specially imported four five-axis, five-side high-speed processing machines from Deckel Maho of Cildemeister, Germany's largest machine tool production group. They have high cutting force, power and precision. Not only can they In addition to setting the mold to process five sides at one time, it can effectively increase the accuracy by more than four times. The high-speed ratio can also greatly increase the delivery speed.

Die Casting Machine:

We have introduced 5 hot chamber die casting machines and 4 cold chamber die casting machines to meet the various needs of customers.