ABOUT

JING-JANG

In order to ensure the accuracy of the mold opening schedule and the quality of the mold, we have established a set of standard mold opening procedures. Through our standard procedures, we communicate with customers to better meet their mold opening needs.

The standard procedure is as follows:

1

2

3

4

5

6

7

8

9

10

Mold design

Mold build

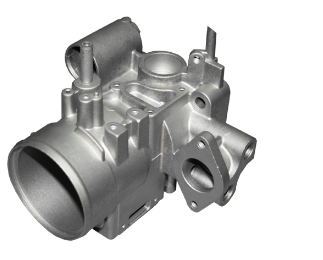

Sophisticated casting

Quality check

Good finish product

One time delivery

Customer satisfy

Die casting

Stamping

Grinding Wheel

CNC Milling

Quality Inspection

Finished Product